Room 406, Unit H038, No. 4, Huating Road, Tianhe District, Guangzhou City +86-13724800004 [email protected]

Features:

· Zero Smoke: Innovative technology eliminates smoke and dust at the source, eliminating yellowing of walls, furniture, and Buddha statues, making breathing easier.

· Authentic Fragrance: Extracted from natural sandalwood essence, the aroma is mellow and elegant, retaining the tranquil charm of traditional sandalwood.

· Safer: Available with either open flame or no open flame design (selectable depending on product type), eliminating the worry of sparks and ensuring peace of mind.

· Super Worry-Free: No need to clean up incense ash, keeping your environment tidy at all times.

Suitable for:

· Creating a relaxing atmosphere while meditating, reading, or drinking tea

· Purifying the air and refreshing the mind in bedrooms, studies, and offices

· Enhancing the atmosphere in public places like hotels and yoga studios

Specifications:

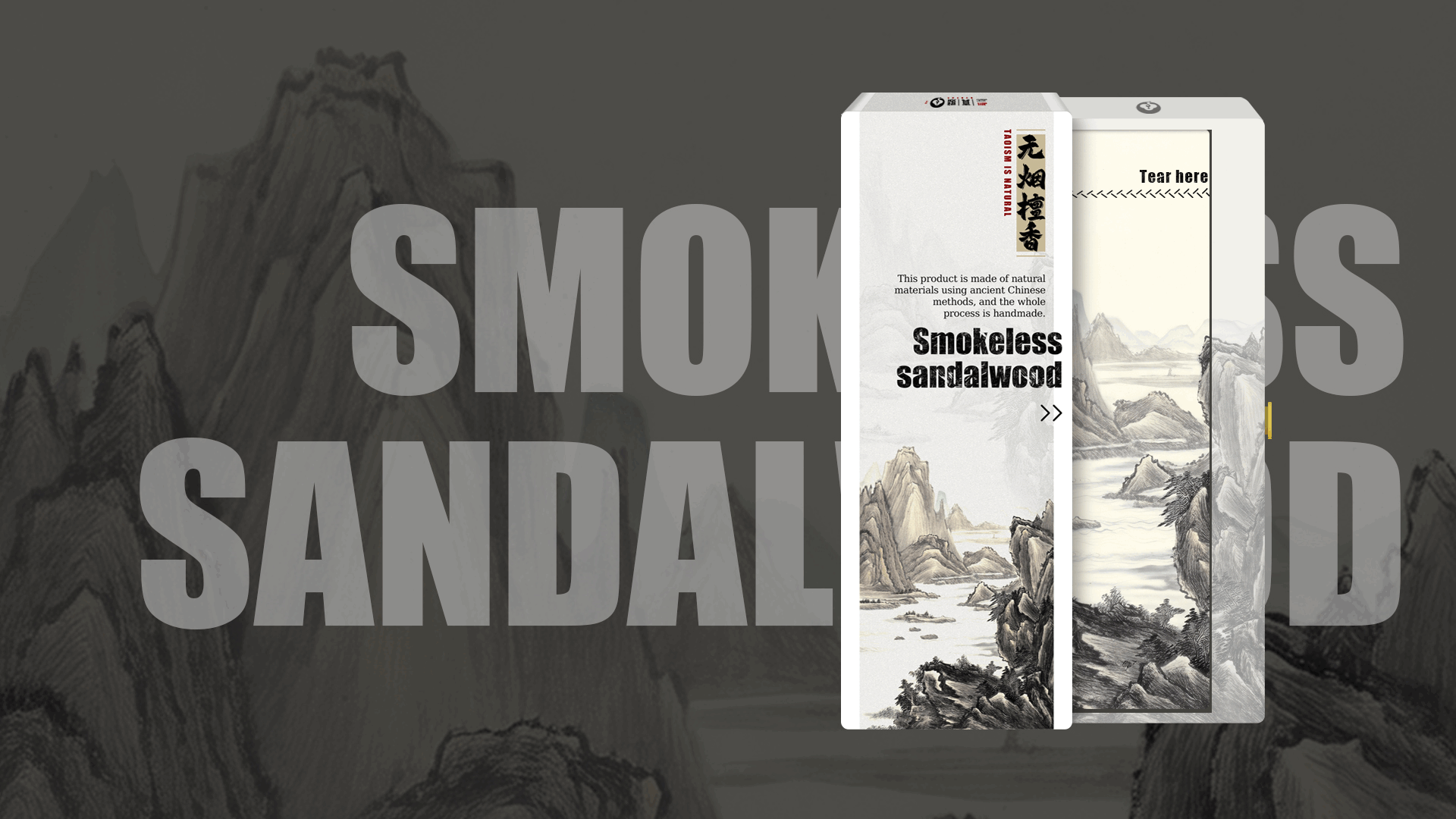

Product Specifications: 28*10*4cm per box. A standard box contains approximately 100-120 pieces, subject to actual delivery.

Standard weight: 200g

Smokeless Sandalwood: The Integration of Traditional Fragrance and Modern Technology

In the culture of incense, sandalwood is highly favored for its warm and mellow aroma. However, the smoke and dust generated during the burning of traditional sandalwood often cause troubles in home - use or meditation scenarios. The emergence of smokeless sandalwood not only retains the core charm of sandalwood, but also solves the pain - points of traditional incense products through technological innovation, making it a popular choice in the modern fragrance market.

In terms of production principle, the core of smokeless sandalwood lies in "removing smoke and retaining fragrance", which requires three major links: raw material selection, process optimization, and technical support. In terms of raw materials, it does not directly use sliced traditional sandalwood. Instead, it selects high - quality sandalwood from excellent producing areas such as Mysore in India and Australia. Through low - temperature extraction technology, natural sandalwood essential oil or balm is extracted, and then matched with natural plant adhesives (such as gum arabic, cassava starch) and smokeless fillers (such as bamboo charcoal powder, plant ash). This proportion can firmly lock the milky - sweet aroma of sandalwood, and avoid the smoke generated by the burning of wood fibers in traditional incense products. The porous structure of the filler can also adsorb the trace impurities that may be generated during burning, further reducing dust release.

In terms of production process, smokeless sandalwood breaks through the limitation of traditional "burning - type incense making", and has derived two main forms. One is "heating - type smokeless sandalwood", which heats sandalwood blocks or slices through electric heating plates or constant - temperature aroma diffusers, and stimulates the aroma by heat. There is no open flame or burning throughout the process, eliminating smoke from the source. The other is "improved burning - type smokeless sandalwood". By adjusting the particle size of raw materials (grinding sandalwood powder to more than 200 meshes) and controlling the proportion of adhesives, the incense body burns more fully. At the same time, a flame - retardant coating is added to the incense core to slow down the burning speed and reduce smoke. Some high - end products will also go through the "aging" process to make the aroma more stable and avoid pungent odors during heating.

In terms of uses, smokeless sandalwood is perfectly suitable for modern diverse scenarios. In home life, placing a heating - type smokeless sandalwood in the bedroom and turning it on before going to bed can release a warm aroma, helping to soothe the nerves and improve sleep, and will not irritate the respiratory tract due to smoke. When used in the living room, its elegant fragrance can replace chemical air fresheners, adsorb odors and enhance the style of the home. Guests will not feel uncomfortable due to the thick smoke. In meditation and relaxation scenarios, matching smokeless sandalwood during meditation or yoga, there is no need to worry about smoke interfering with breathing. The aroma can guide users to focus quickly, especially suitable for beginners or use in enclosed spaces. In addition, smokeless sandalwood also shows its advantages in office and public places. Using it in the office can dispel fatigue and improve concentration, without the hyperactivity caused by coffee. Using it in hotels, yoga studios and other places can not only create an elegant atmosphere, but also meet the requirements of fire safety and air environmental protection.

Compared with traditional sandalwood, smokeless sandalwood does not "abandon tradition", but empowers the incense culture with technology, making the thousand - year - old sandalwood fragrance rejuvenate in modern life, and meeting people's dual needs for "natural fragrance" and "healthy life".

Production Process

1. Raw Material Selection

They are choosing high purity sandalwood powder, natural plant binders, and environmentally friendly combustion agents. In order to get the typical smokeless sandalwood result, all the materials have to be free of synthetic fragrances, heavy smoke additives, and chemical accelerators.

2. Sandalwood Powder Refining

Sandalwood powder is refined by passing it through a sieve and then it is milled until it reaches ultra-fine particle size. Burning will be more stable, smoke will be less, and the release of the fragrance will be cleaner if the powder is finer. This stage has a direct bearing on the extent to which the smoke will be eliminated.

3. Ingredient Mixing

The mixture of sandalwood powder and the binding agent is done according to the controlled ratio. Water content is very accurately regulated so that the incense will be structurally stable yet it will not produce a lot of smoke when it is burnt.

4. Dough Kneading & Extrusion

After the ingredients are combined, the resultant dough is kneaded until it is uniform and then it is shaped into incense sticks by the process of extrusion with the help of the specialized machinery. Consistent density is very important for the Smokeless sandalwood burn profile.

5. Drying Process

The drying of the incense sticks is done in a room where the humidity is controlled and it takes about 48–72 hours. The correct drying is the prevention of cracks, it ensures that combustion will be even and smoke surges will not occur. Modern airflow systems make it possible for each stick to attain its ideal moisture level.

6. Surface Polishing & Finishing

Once the sticks are dried, they go through a stage where they are softly polished so that dust present on their surface can be removed and they can have a smooth look. It also helps in stabilizing the burning speed and the production of a pure sandalwood scent.

7. Packaging

Finally, incense sticks are packed in packages that are moisture-proof and environmentally friendly so as to keep the product fresh and maintain the aroma. Traceability is provided for each batch through labeling.

Quality Control & Testing Steps

1. Material Purity Testing

Each batch of sandalwood powder is subjected to a purity test to avoid the addition of artificial scent, the use of harmful chemicals, or the presence of any impurities that may affect the properties of the Smokeless sandalwood.

2. Moisture & Density Inspection

Consistent density and moisture levels are ensured by measuring random samples. These two dimensions are very important for a completely smokeless combustion.

3. Combustion Test

Several sticks from each batch undergo a fire test in a controlled manner. The inspectors evaluate:

Smoke output (must meet smokeless standard)

Aroma purity

Burn speed and stability

Ash color and residue consistency

Those sticks which fail to deliver the full Smokeless sandalwood effect are rejected.

4. Structural Integrity Check

The hardness, flexibility, and resistance to breaking of the incense sticks are tested. Any stick with a crack or deformity is discarded.

5. Final Packaging Inspection

Packaging is checked for airtight sealing, correct labeling, and product safety before the shipment.